Note: For all industrial 3D printing see Stratasys.com Material List

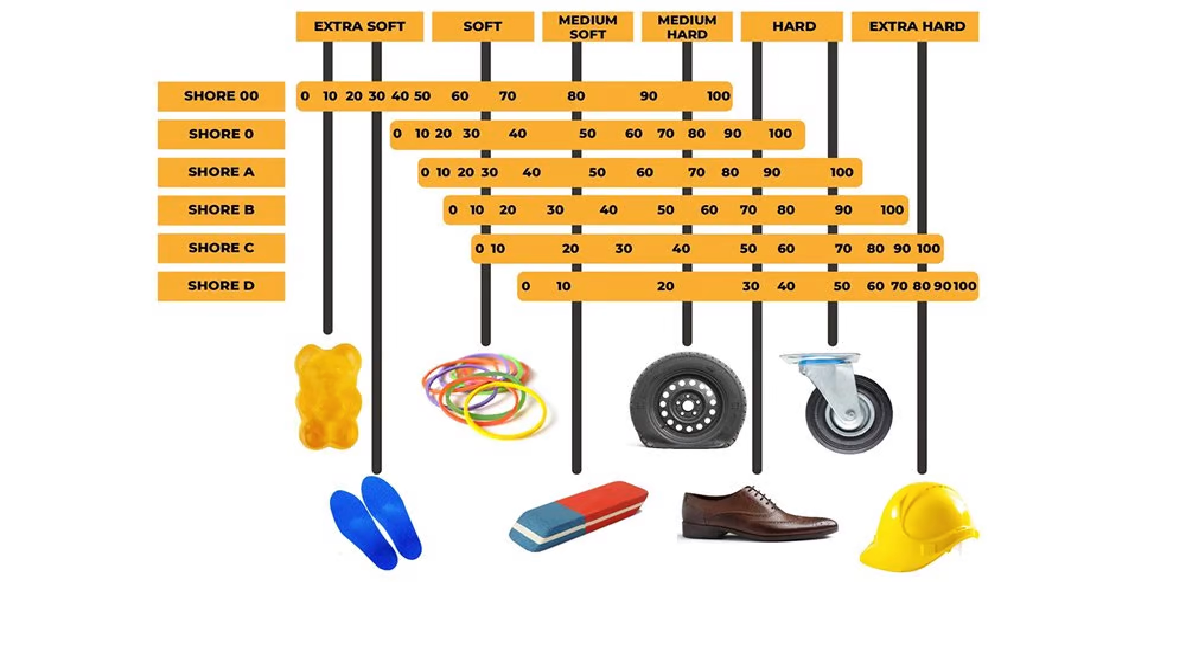

Shore Hardness

Shore hardness is a common term you’ll hear when it comes to polymers for fileable 3D printer Filament, but it’s more general than the more technical measurements like Young’s modulus or elongation at break. For example, most flexible filament would be Shore A, and within the A category they would have individual values, such as Shore hardness 95A. You may also see Shore values in the C or D category, which more often denote hard rubbers and semi-rigid plastics. The most common Shore value for flexible filaments is 95A. Using the chart below will help you determine what TPU 3D printer filament to buy.

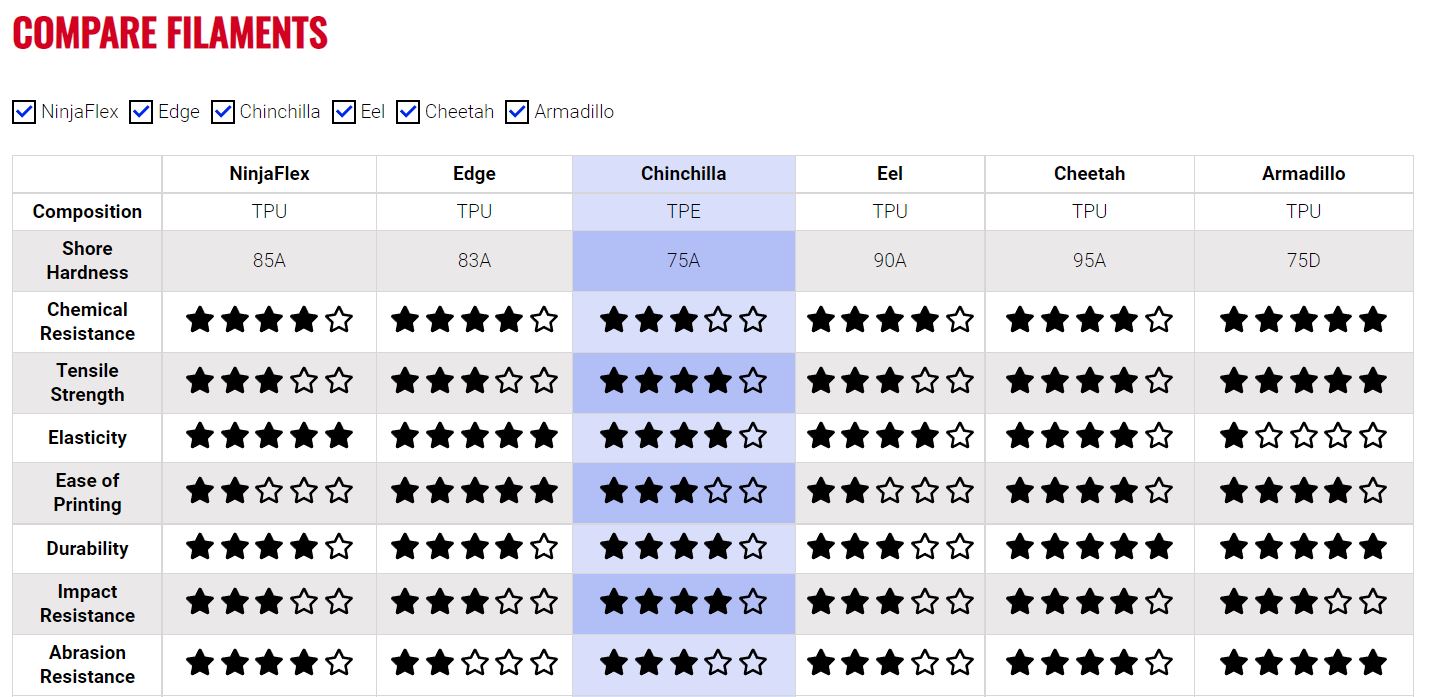

Some examples from NINJATEK:

- Use NinjaFlex® (85A) for grip pads, vibration dampening, shock absorption, gaskets, seals, guards and soft robotics. For RC tires, seals and gaskets.

- Use Cheetah® (95A) for assembly line jigs, fixtures, ergonomic improvements, guards and shock absorption.

- Use Armadillo® (75D) for jigs, fixtures, ergonomic improvements, proof-of-concept gears, sprockets, shipping inserts, textured rollers and small part replacements. For medical for prosthetic sockets and shells.

- Use Eel™ (90A) for robotic grippers. TPU 3D printing filament is a conductive, static dissipative and flexible material.

- Use Chinchilla™ (75A) for prosthetic liners and organ printing (pre-surgery prep or teaching hospitals). for clothing, cosplay costumes and wearables such as watch bands. for non-marking applications.

Site Info: link